Description

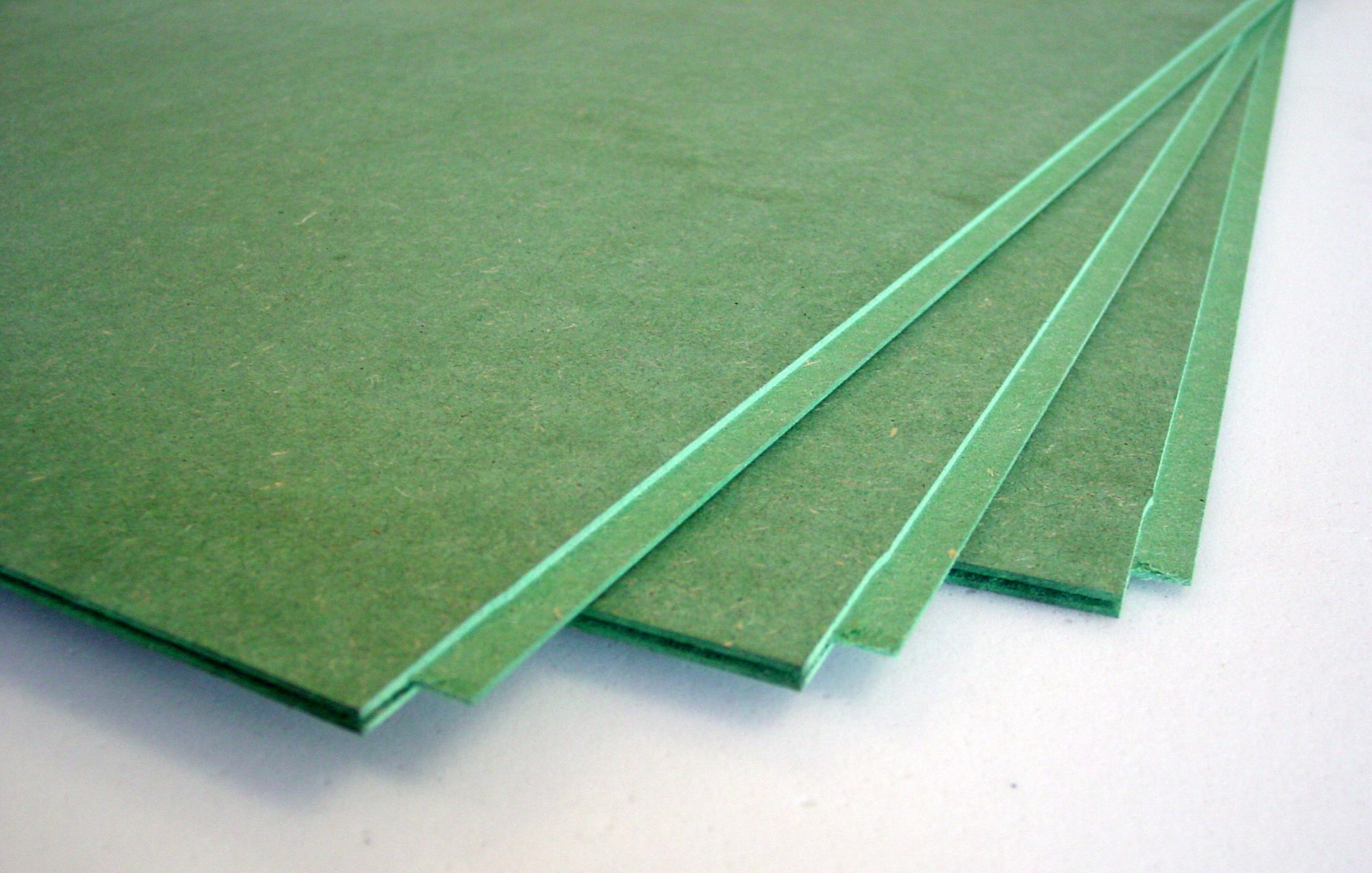

Moisture resistant Tongue & Groove MDF Panels are available in two sizes 6mm (panel size 1200mm x 1200mm) and 9mm (Panel size 1200mm x 596mm)

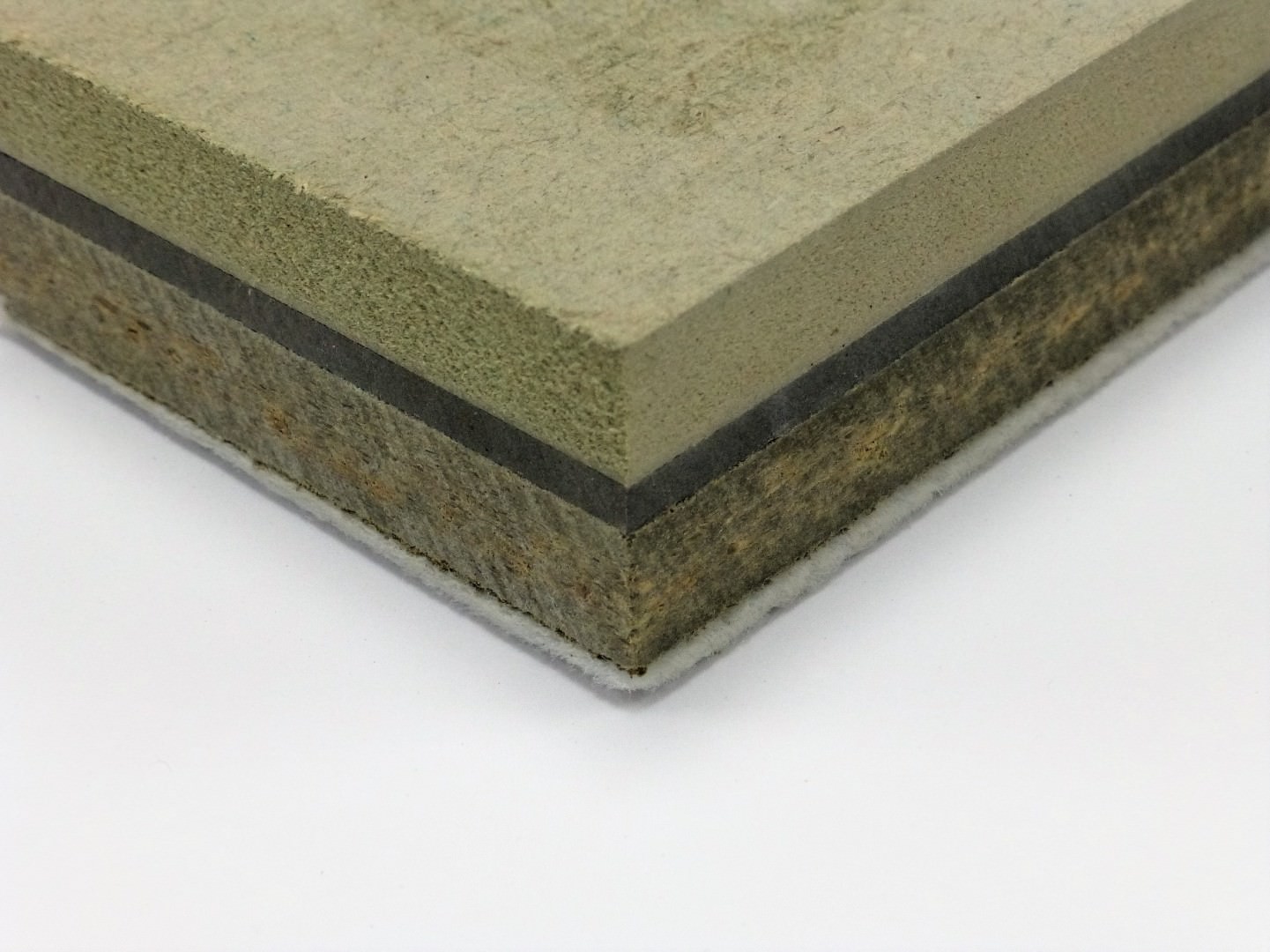

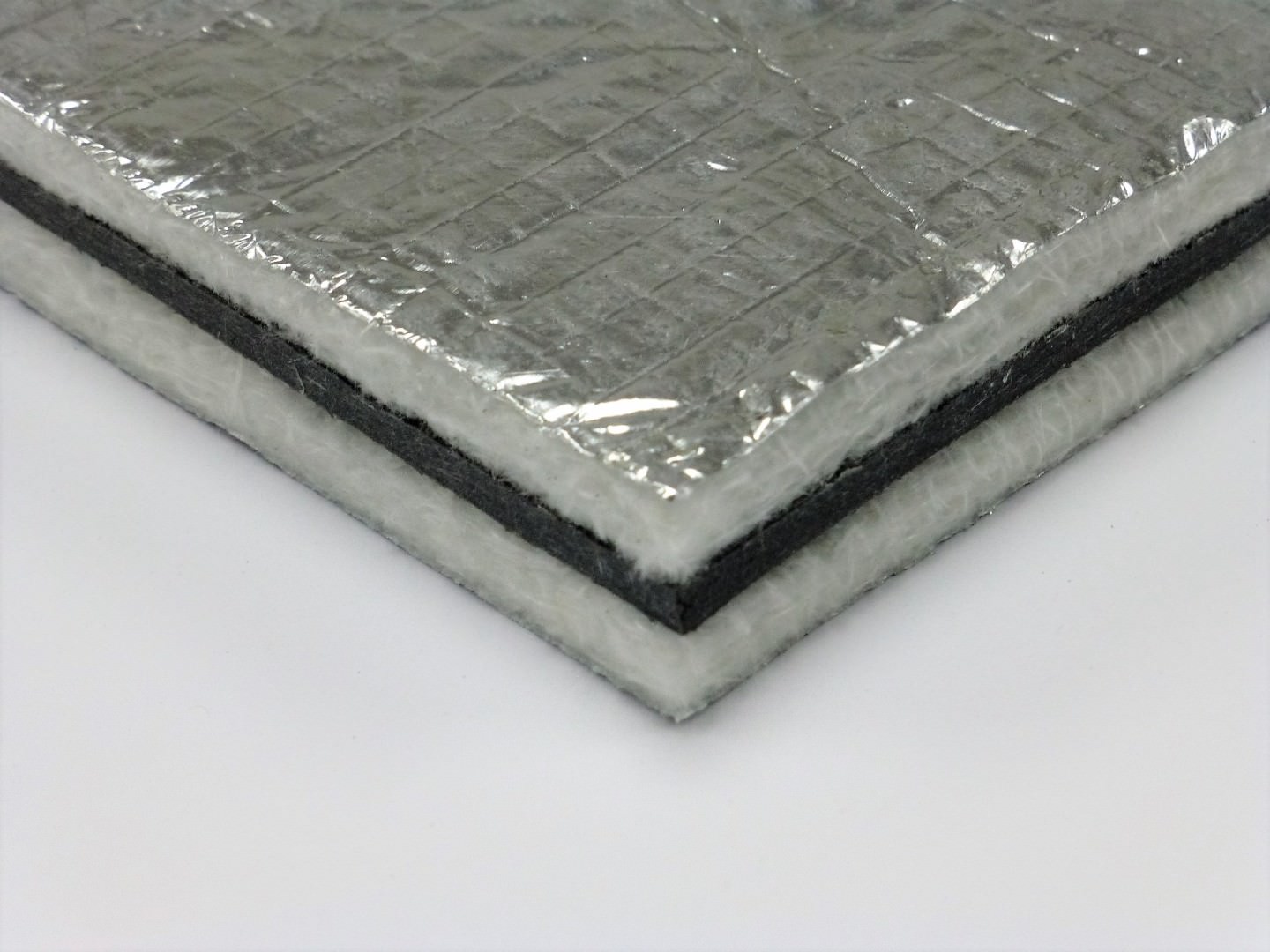

When installing Acoustilay beneath laminate flooring, vinyl flooring, carpet tiles, or bonded carpet, it is necessary to install MDF between the Acoustilay and the floor finish. The use of Acoustilay MDF improves stability for the floor finish and prevents problems due to point loading, carpet rucking, and joint damage to the floor finish. in the case of bonded carpet and carpet tile floor finishes the use of MDF will also aid the installation by giving a stable surface to bond to. MDF should be bonded to the top of Acoustilay with SRS Acoustilay adhesive. The MDF boards should be bonded to each other using a PVA adhesive on the t&g joints, and any such joint should be a minimum of 50mm away from any Acoustilay joint, an isolation gap of 5mm should be left between the wall and the Acoustilay MDF to avoid sound transmission flanking into the structure, the isolation gap should be filled with acoustic sealant. The floor finish should then be installed on top of the Acoustilay MDF as per the manufacturer’s instructions. For confirmation on the suitability of any engineered timber floor for use with Acoustilay, please check with the floor finish manufacturer prior to installation. if the floor manufacturer feels that the resilience of the Acoustilay is excessive, or if the installation occurs anywhere other than a domestic environment, SRS recommend that the timber floor should be supported by installing a layer of MDF, bonded to the top of the Acoustilay. In this situation the full instructions of the ‘laminate, vinyl, carpet tile, Bonded carpet floor finishes‘ section should be followed.