Description

Acoustic insulation innovators, Sound Reduction Systems, are proud to announce revolutionary new changes to their market leading soundproofing acoustic underlay product, Acoustilay.

Years of research and development have resulted in the creation of a product that is 100% recyclable, manufactured entirely in the UK, and that maintains all of the acoustic properties of the previous product

The issue of sustainability in buildings has long been a major factor for specifiers when considering products for their projects. Houses can also be awarded ‘points’ for their acoustic and thermal insulation properties. Sound Reduction Systems have now combined both acoustic and environmental properties within their Acoustilay range, ensuring peace of mind in terms of acoustic performance and environmental impact, both with specifier and end user.

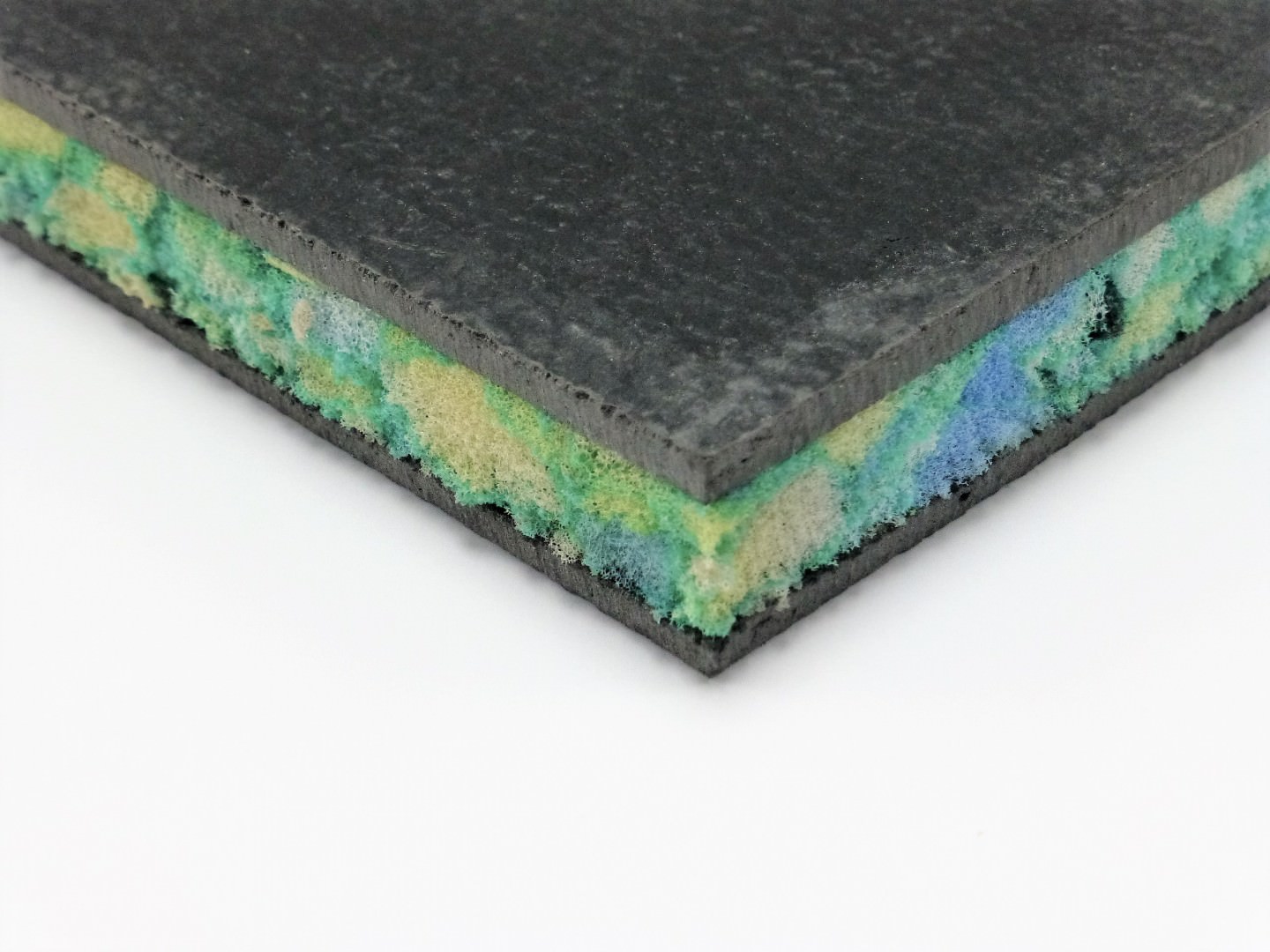

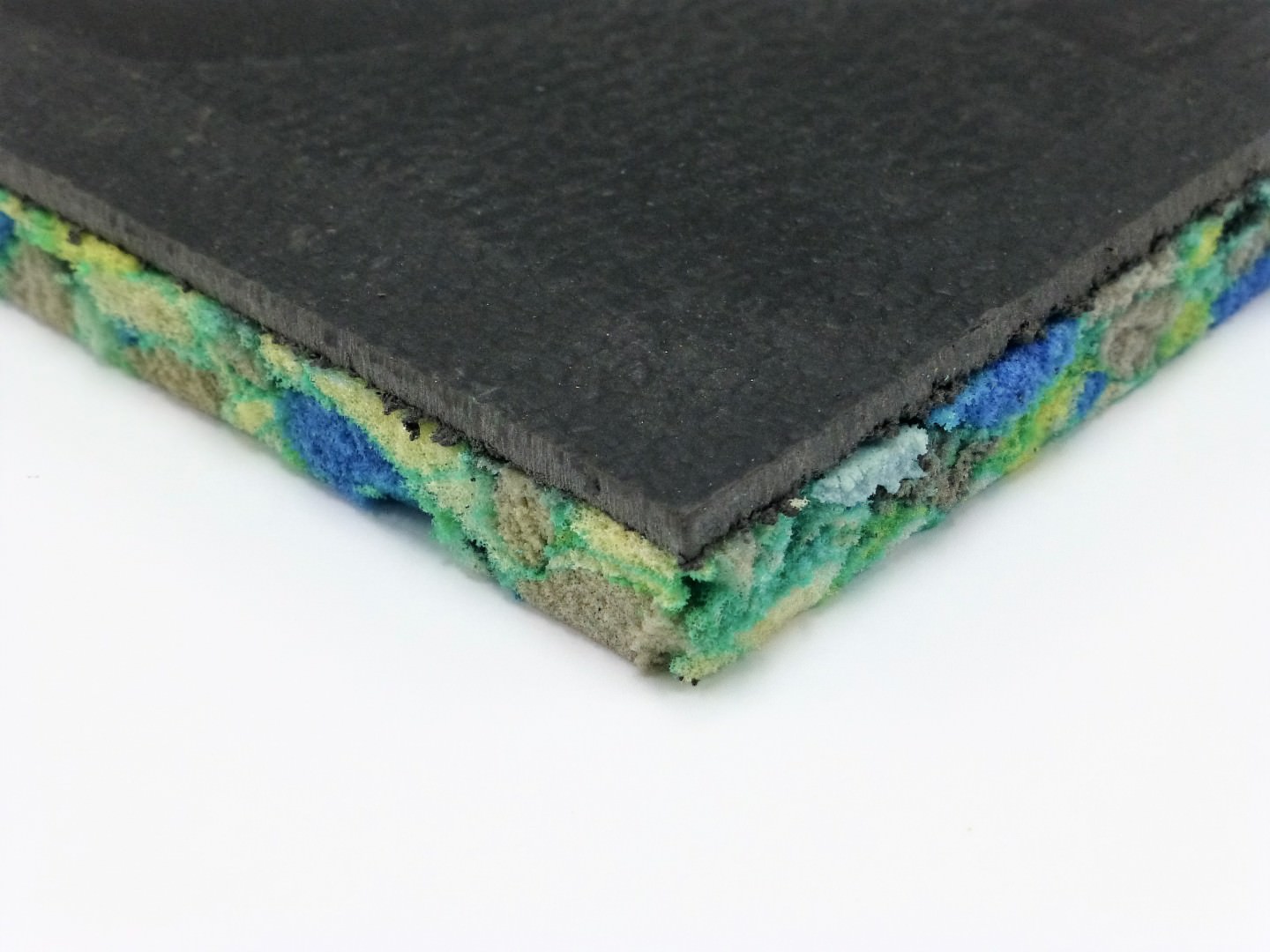

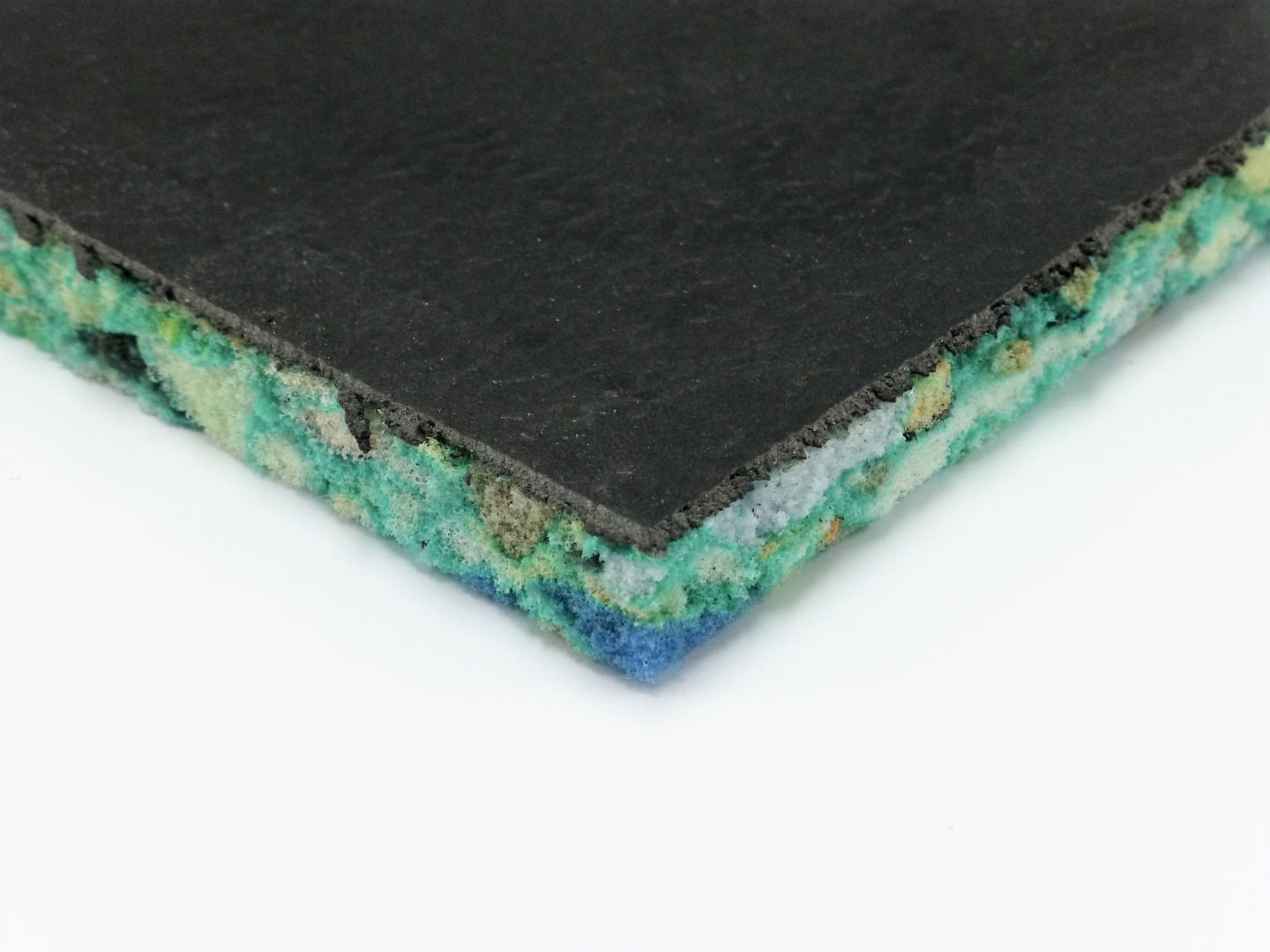

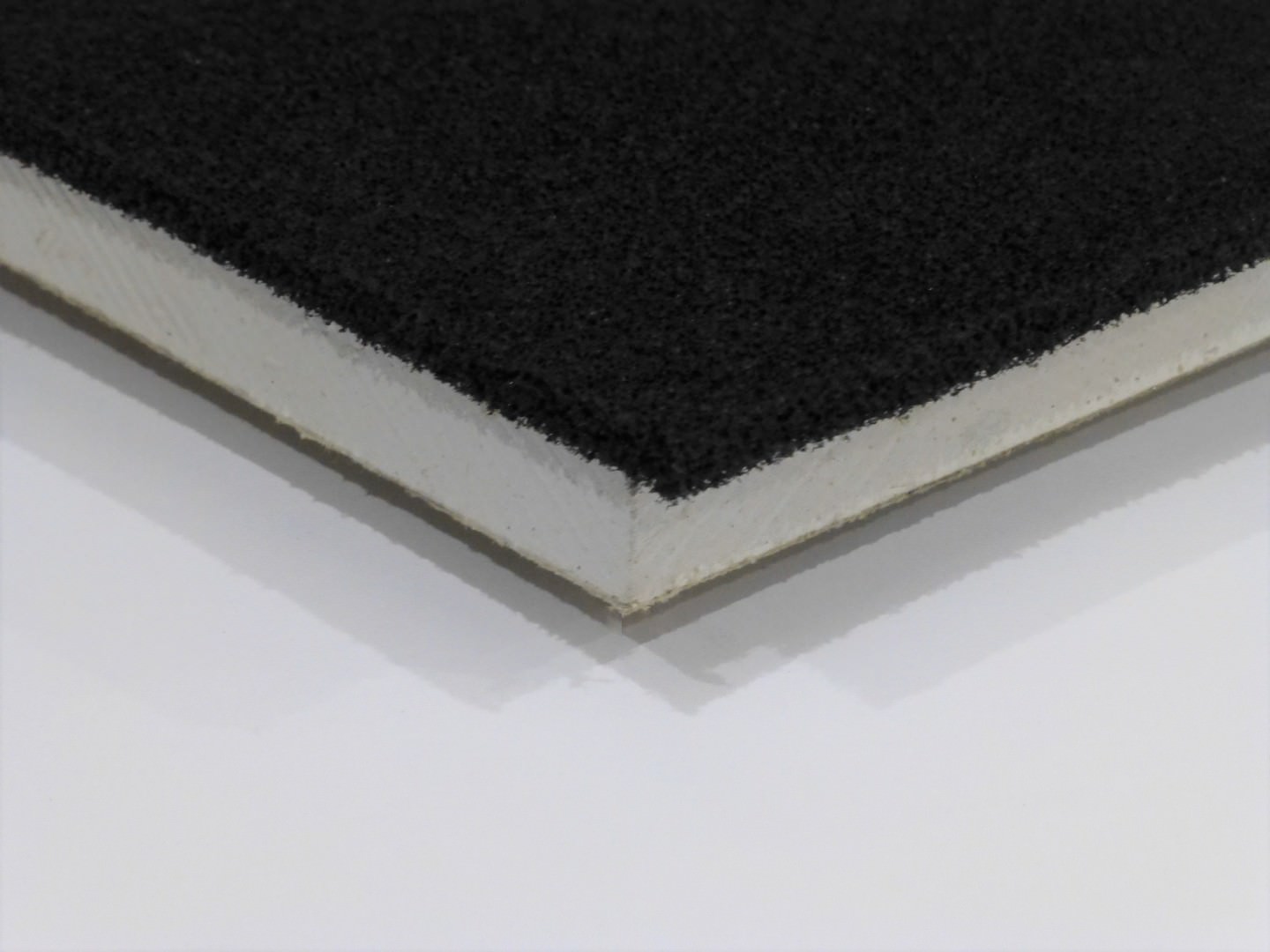

Acoustilay is manufactured entirely in the UK, therefore reducing the carbon footprint associated with imported goods. The barrier mat material, used to give Acoustilay mass, can be manufactured from pre, mixed and post industrial waste sources and is 100% recyclable at the end of its life. The unique PVC free material has a proprietary polymer structure which ensures it is one of the least polluting plastics, and does not emit any toxic compounds when it burns. New Acoustilay is green in colour so specifiers, contractors and clients can be sure that the material on site is the new Acoustilay.

Acoustilay has long been a firm favourite with specifiers and end users due to its high acoustic performance, and ease of installation, and is often used to meet the requirements of Building Regulations Part E in flat conversions. However, Acoustilay is also widely used by people to simply upgrade the sound insulation of floors in their own properties for personal comfort.